Overview

Sheet Laser cutting is a high-speed, non-contact cutting technology that delivers clean, precise cuts with minimal material waste. It is widely used in automotive, construction, metal fabrication, and interior design industries for processing both metal and non-metal sheets.

How It Works

A high-powered laser beam focuses on the sheet surface, generating heat to melt or vaporize the material. Assist gases like oxygen or nitrogen remove molten material, ensuring a smooth, burr-free finish.

Key Advantages

- Extreme Precision – Cuts with tolerances below 0.1 mm

- Fast Processing – Boosts production speed and efficiency

- No Need for Molds – Ideal for custom production and prototyping

- Minimal Waste – Maximizes material usage

- Smooth, Clean Edges – Reduces need for secondary finishing

Sheet Laser Cutting vs. Traditional Methods

Unlike mechanical sawing or plasma cutting, sheet laser cutting offers:

- Higher accuracy and intricate design capability

- Faster processing with less heat distortion

- Lower material waste, optimizing production costs

Optimizing Laser Cutting for Maximum Efficiency

Energy Consumption Reduction – Modern laser cutting systems optimize power usage, reducing operational costs while maintaining high performance.

Advanced Cooling Systems – Integrating efficient cooling mechanisms prevents overheating and extends machine lifespan.

Automation & Smart Control – AI-driven automation improves precision, reduces human error, and enhances workflow efficiency.

Multi-Material Capability – New-generation lasers support cutting a wider range of materials, including composites and specialized alloys.

Innovative Uses of Sheet Laser Cutting

- Smart Manufacturing – Integration with IoT and Industry 4.0 technologies for real-time monitoring and optimization.

- Customization & Prototyping – Ideal for rapid prototyping and small-batch custom production with minimal material waste.

- Architectural & Artistic Design – Creating intricate metal structures, decorative panels, and unique design elements.

- Marine & Shipbuilding – Precision cutting of corrosion-resistant materials for marine applications.

- Food Processing Equipment – Manufacturing stainless steel components with sanitary, contamination-free cuts.

Revolutionizing Manufacturing with Laser Cutting

The future of sheet laser cutting is driven by automation, AI, and sustainable manufacturing. With increasing demand for efficiency and precision, industries adopting advanced laser cutting technology will gain a competitive edge. Soha group is committed to delivering state-of-the-art solutions, helping businesses achieve higher productivity and innovation.

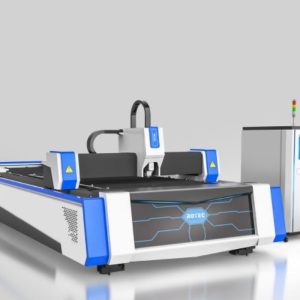

Laser Sheet Cutting products

Looking for Reliable Industrial Solutions?

Boost Your Production with Soha Group

Laser Cutting | Laser Welding | Press Brakes | Guillotine cutter