Overview

Rotary laser cutting is a specialized technology designed for cutting cylindrical parts, tubes, and metal or non-metal profiles with exceptional accuracy. It offers high-speed performance and minimal material waste, making it a preferred solution in industries such as automotive, furniture, pipe manufacturing, and industrial equipment production.

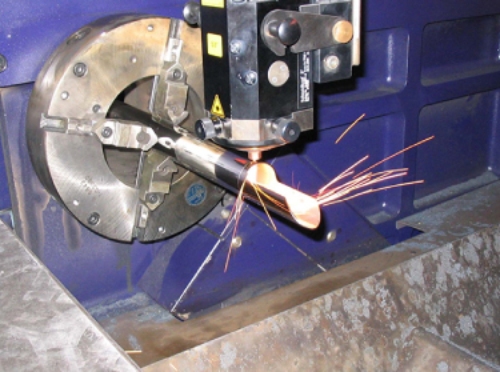

How It Works

This method combines a high-powered laser beam with a rotary axis, allowing seamless rotation of the workpiece while the laser precisely executes cuts, grooves, and perforations. The synchronization of rotation and laser beam ensures clean and uniform edges, even on complex curved surfaces.

Key Advantages

- Unmatched Precision – Ideal for intricate cuts and designs on tubular structures

- Fast & Efficient – Reduces production time and supports mass manufacturing

- No Molds Required – Eliminates additional tooling costs and improves flexibility

- Smooth, Clean Cuts – Minimal need for secondary finishing

- Perfect for Complex Angles & Shapes – Overcomes limitations of conventional cutting methods

Why Choose Rotary Laser Cutting Over Traditional Methods?

Unlike mechanical sawing, plasma cutting, or CNC machining, rotary laser cutting provides:

Higher speed & efficiency

Reduced thermal impact

Greater accuracy in curved and angled cuts

Minimal material waste

Common Challenges & Solutions

Inaccurate angle cuts? Adjust rotational speed and enhance laser synchronization

Burr formation? Use nitrogen gas to prevent oxidation buildup

Misalignment in long pipes? Implement stable support systems for vibration control

Industry Applications

- Automotive – Cutting exhaust systems, chassis components, and decorative trims

- Furniture & Interior Design – Crafting decorative metal structures and railings

- Pipe Manufacturing – Processing industrial steel and aluminum tubes

- Sports Equipment – Shaping bicycle frames and fitness structures

- Heavy Machinery – Producing precision components for industrial applications

Final Thoughts

Rotary laser cutting enhances efficiency, precision, and cost-effectiveness in manufacturing. By eliminating the constraints of traditional methods, this technology revolutionizes tube and profile processing for various industries. Soha group offers cutting-edge rotary laser machines, ensuring top-tier performance for industrial needs.

Rotary Laser Cutting products

Looking for Reliable Industrial Solutions?

Boost Your Production with Soha Group

Laser Cutting | Laser Welding | Press Brakes | Guillotine cutter