Overview

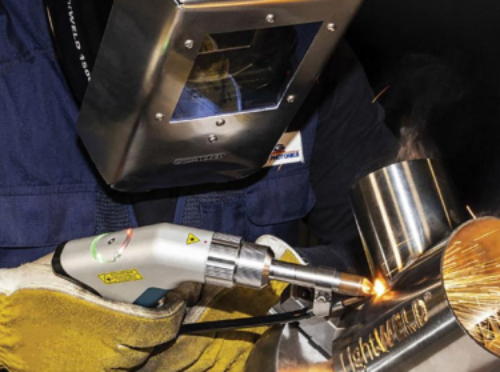

Laser welding is a non-contact technology that uses a focused laser beam to join metal and non-metal components with exceptional strength and minimal thermal distortion. It is widely used in industries such as automotive, electronics, aerospace, and medical manufacturing.

How It Works

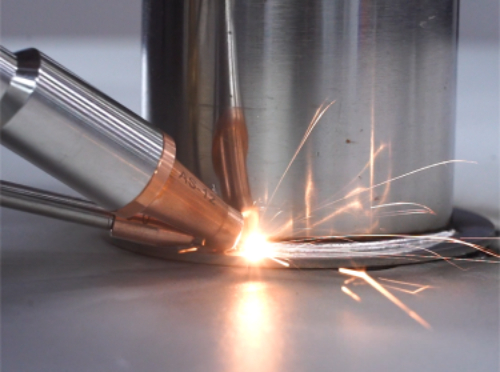

A high-powered laser beam melts and fuses materials at the joint, forming a strong and uniform weld. Shielding gases like argon and nitrogen prevent oxidation, ensuring superior weld quality.

Advantages of Laser Welding

- High precision with minimal heat-affected zones

- Fast processing speed, reducing production time

- Non-contact process, minimizing tool wear

- Ability to weld various metals and composites

- Superior surface quality, reducing post-processing needs

Comparison with Traditional Welding

Unlike arc or resistance welding, laser welding offers higher precision, lower energy consumption, and minimal material distortion, making it ideal for delicate and high-strength applications.

Common Challenges & Solutions

- Cracks in the weld: Adjust welding speed and use shielding gases

- Gas porosity: Ensure surface cleaning before welding

- Insufficient penetration: Optimize laser power settings

- Reflection issues in metals like aluminum: Use specialized lasers and coatings

- Material warping: Utilize pulsed welding techniques and controlled cooling

Applications in Key Industries

- Automotive: Welding sensors, electronic parts, and body components

- Medical: Manufacturing surgical instruments and implants

- Aerospace: Joining high-strength alloys and turbine components

- Jewelry: Seamless repairs and precision welding of gold and silver

- Battery & Energy: Welding lithium cells and solar panels

Soha group provides state-of-the-art laser welding machines with expert consultation, reliable warranty, and ongoing technical support to ensure high-quality production across various industries.

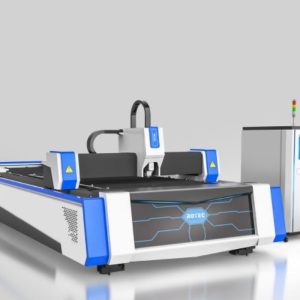

Laser Welding products

Looking for Reliable Industrial Solutions?

Boost Your Production with Soha Group

Laser Cutting | Laser Welding | Press Brakes | Guillotine cutter