Overview

A laser machine is an advanced tool used for cutting, engraving, marking, and welding various materials with high precision and speed. These machines operate by directing a concentrated laser beam onto a surface, melting, burning, or vaporizing the material to create intricate designs or precise cuts. Laser machines are widely used in metalworking, woodworking, signage, jewelry, electronics, and industrial manufacturing due to their efficiency, accuracy, and versatility.

How It Works

A laser machine generates a high-energy laser beam using different types of laser sources such as CO₂, fiber, or diode lasers. The beam is directed through a lens system and focused on the material, where it either cuts, engraves, or marks based on the machine’s settings.

Key components of a laser machine include:

-

Laser Source – Generates the laser beam (CO₂, fiber, diode, or UV).

-

Optics & Lens System – Focuses the beam on the material.

-

Gantry & Motion System – Moves the laser head along the programmed path.

-

Cooling System – Prevents overheating of components.

-

Exhaust & Filtration – Removes smoke and debris from the work area.

-

Control Software – Allows users to set parameters for cutting, engraving, or marking.

Advantages of Laser Machines

-

High Precision – Cuts and engraves with extreme accuracy.

-

Non-Contact Processing – Reduces mechanical wear and material deformation.

-

Speed & Efficiency – Faster than traditional cutting and engraving methods.

-

Versatile Material Compatibility – Works with metals, wood, plastic, glass, leather, and more.

-

Minimal Waste – Creates clean cuts with reduced material loss.

-

Automated Operation – Compatible with CNC and CAD software for detailed designs.

Types of Laser Machines

CO₂ Laser Machines

CO₂ laser machines use a gas mixture (CO₂, nitrogen, helium) to generate the laser beam. They are best suited for engraving and cutting non-metal materials like wood, acrylic, leather, and glass. These machines are commonly used in sign-making, crafting, and packaging industries.

Fiber Laser Machines

Fiber laser machines use a fiber-optic laser source, making them ideal for cutting and marking metals such as stainless steel, aluminum, and brass. These machines are widely used in industrial metal fabrication, automotive, and aerospace sectors.

Diode Laser Machines

Diode lasers are compact, energy-efficient, and affordable, making them suitable for engraving wood, leather, and plastics. These are often used by hobbyists, small businesses, and desktop applications.

UV & Green Laser Machines

These specialized lasers are designed for delicate engraving on glass, plastics, and circuit boards. They are commonly used in medical device manufacturing, electronics, and high-precision marking applications.

Challenges & Solutions

Some common challenges when using laser machines include:

-

Burnt Edges on Wood & Acrylic – Adjusting power and speed settings or using air assist can help achieve cleaner cuts.

-

Inconsistent Engraving Depth – Proper focus and laser intensity adjustments ensure even engraving.

-

Overheating of Materials – A well-maintained cooling system and proper ventilation reduce overheating risks.

-

Metal Cutting Issues – Choosing the right fiber laser wattage for the material thickness improves cutting efficiency.

Applications Across Industries

Laser machines play a crucial role in various industries, including:

-

Metal Fabrication – Cutting and engraving metals for industrial applications.

-

Signage & Advertising – Creating custom acrylic and metal signs.

-

Jewelry Making – Precision engraving and cutting of fine jewelry designs.

-

Automotive & Aerospace – Cutting and marking components with high durability.

-

Electronics – Laser etching and circuit board marking.

-

Textile & Fashion – Engraving patterns on leather and fabrics.

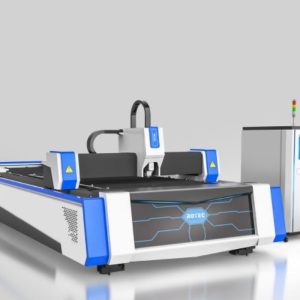

Laser machine products

Looking for Reliable Industrial Solutions?

Boost Your Production with Soha Group

Laser Cutting | Laser Welding | Press Brakes | Guillotine cutter