Overview

Laser cutting is an advanced material processing method that uses a concentrated laser beam for precise and efficient cutting of various materials. It is widely used in industries such as metalworking, automotive, advertising, electronics, and interior design due to its high precision, speed, and minimal waste.

How It Works

A high-energy laser beam focuses on the material, melting, vaporizing, or burning it to create a clean cut. Assist gases such as oxygen and nitrogen help remove molten material, ensuring a smooth finish.

Advantages of Laser Cutting

- High precision with minimal material waste

- Faster processing compared to traditional methods

- No direct contact, reducing tool wear and mechanical stress

- Ability to cut a wide range of materials, including metals, wood, plastic, and glass

Types of Laser Cutting

- Sheet Metal Laser Cutting – Ideal for steel, aluminum, and industrial manufacturing

- Rotary Laser Cutting – Suitable for cylindrical objects and decorative components

Comparison with EDM

Laser cutting is faster and cost-effective for large-scale production, while EDM offers extreme precision but is slower and more expensive.

Challenges & Solutions

- Rough Edges: Adjust laser power and use nitrogen for clean cuts

- Edge Discoloration: Use nitrogen or argon instead of oxygen

- Precision Issues: Optimize lens focus and cutting speed

- Declining Cut Quality: Regular maintenance and lens cleaning

Applications Across Industries

- Automotive: Cutting precision parts

- Advertising & Interior Design: Acrylic signage, 3D letters

- Electronics: Circuit board engraving

- Metal & Construction: Structural components, security doors

Soha group provides cutting-edge laser cutting machines with expert consultation, reliable warranty, and ongoing technical support, ensuring businesses find the best solutions for their industrial needs.

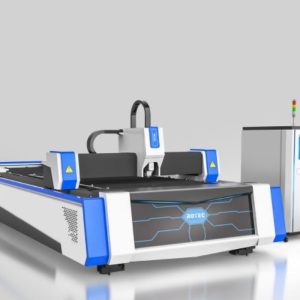

Laser Cutting products

Looking for Reliable Industrial Solutions?

Boost Your Production with Soha Group

Laser Cutting | Laser Welding | Press Brakes | Guillotine cutter