Overview

A guillotine cutter is a precision cutting tool designed for slicing materials such as paper, plastic, textiles, and even soft metals. It operates using a sharp, straight blade that moves in a downward motion, ensuring clean and accurate cuts. Guillotine cutters are widely used in industries like printing, bookbinding, packaging, and bakery production, offering efficiency and consistency in mass cutting operations.

How It Works

Guillotine cutters utilize a lever-action or automated mechanism to lower a sharp, straight-edged blade onto the material, slicing it cleanly. Depending on the model, they can be manual, semi-automatic, or fully automatic.

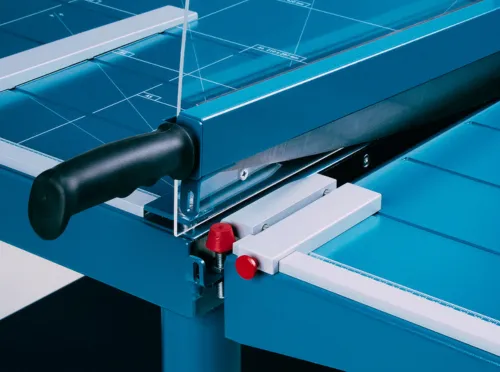

Key Components:

Blade – Made from hardened steel for sharp, precise cutting.

Clamp System – Holds the material in place to prevent movement.

Cutting Table – Provides stability for accurate measurements.

Safety Features – Includes blade guards, safety locks, and dual-hand operation on industrial models.

Guillotine cutters are available in different sizes, from compact office trimmers to heavy-duty industrial machines designed for cutting stacks of paper, cardboard, or food products.

Key Features and Advantages

Precision Cutting: Guillotine cutters deliver highly accurate cuts, which is essential in high-quality printing and professional binding operations.

Versatility: They are designed to handle various materials and thicknesses—from paper and cardboard to light plastics—making them suitable for both office and industrial environments.

Ease of Use: With user-friendly controls and adjustable settings, these cutters help operators achieve repeatable, consistent results with minimal training.

Speed and Efficiency: High-performance models can process large volumes quickly, reducing production times in busy workspaces.

Types of Guillotine Cutters

1. Paper Guillotine Cutters

Designed for offices, print shops, and bookbinding.

Cuts large stacks of paper in a single motion.

Available in manual, electric, and hydraulic models.

2. Industrial Guillotine Cutters

Heavy-duty machines for packaging, textile, and metal sheet industries.

Used for mass production with programmable settings.

Often computer-controlled (CNC) for enhanced precision.

3. Guillotine Bakery Cutters

Used in the food industry for slicing dough, pastries, and other baked goods.

Ensures uniform cuts for consistent product sizes.

Features stainless steel blades for hygiene compliance.

4. Compact Guillotine Trimmers

Small-sized models for crafting, photography, and school use.

Portable and lightweight, with safety locks for home or office applications.

Comparison with Other Cutting Methods

| Guillotine Cutter | Rotary Trimmer | Die Cutting Machine | |

|---|---|---|---|

| Cutting Mechanism | Single blade motion | Rotating circular blade | Pre-shaped cutting dies |

| Precision | High | Very High | Fixed shape precision |

| Material Capacity | Medium to High | Low to Medium | Medium |

| Speed | Fast | Moderate | Slow to Moderate |

| Best Use Case | Mass cutting, stacks | Photo and craft trimming | Custom shape cutting |

| Technical Specs | 1.0d / 2.0d | 7.6d / 5.8d | – |

Challenges & Solutions

| Challenge | Solution |

|---|---|

| Blade Dullness | Regular sharpening or replacement of the blade |

| Paper or Material Shifting | Use built-in clamps for stability |

| Safety Concerns | Ensure blade guards and two-hand operation mechanisms are in place |

| Uneven Cuts | Adjust cutting pressure and use guides for alignment |

Applications Across Industries

Printing & Bookbinding – Used for trimming books, magazines, and brochures.

Packaging – Cutting cardboard, plastic sheets, and packaging materials.

Craft & Design – Precision trimming of photos, posters, and artwork.

Bakery & Food Processing – Slicing uniform portions of bread, pastries, and confectionery products.

Office & School Use – Cutting paper stacks for administrative tasks and classroom projects.

Guillotine Cutter products

Looking for Reliable Industrial Solutions?

Boost Your Production with Soha Group

Laser Cutting | Laser Welding | Press Brakes | Guillotine cutter